Sheet Metal Gauge Chart When working with sheet metal, you often hear the term “gauge.” For those not familiar with…

People often find it confusing to describe steel pipe dimensions or sizes accurately and communicate their requirements to sellers. Misunderstandings or incorrect sizes can lead to significant issues and complications in projects.

So, what are the right ways to express the dimensions of a steel pipe?

For your better understanding, we will explain from the following aspects:

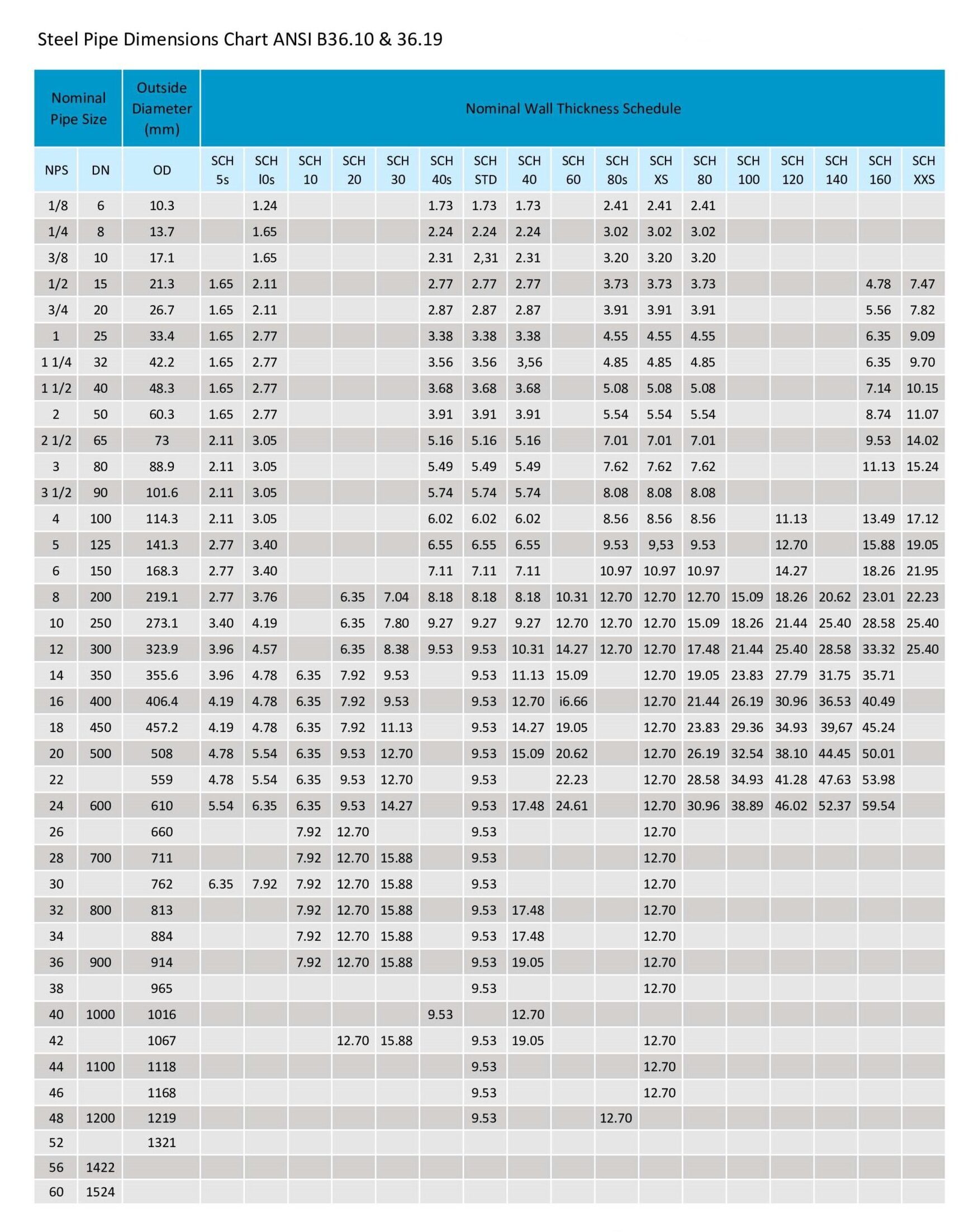

Dimension Standards of carbon and stainless steel pipe (ASME B36.10M & B36.19M)

Pipe Size Schedule (Schedule 40 & 80 steel pipe means)

Means of Nominal Pipe Size (NPS) and Nominal Diameter (DN)

Steel Pipe Dimension Chart (Size chart)

Pipe Weight Class Schedule (WGT)

And finally, we will tell you how to describe steel pipe dimensions & sizes correctly.

Outer diameter (OD), wall thickness (WT), and pipe length, typically either 20 feet (6 meters) or 40 feet (12 meters).

These parameters are essential for various calculations, including determining the pipe’s weight, its pressure-bearing capacity, and the cost per foot or meter.

Accurate knowledge of the correct pipe size is indispensable in engineering, construction, and manufacturing, ensuring optimal performance and cost-efficiency in diverse applications.

There are different standards to describe the steel pipe size, outer diameter (OD), and wall thickness, primarily ASME B 36.10 and ASME B 36.19.

Both ASME B36.10 and B36.19 serve as standard specifications for steel pipe dimensions and accessories.

Standardizes steel pipe dimensions, covering seamless or welded types suitable for various temperature and pressure conditions. Distinguishing pipes from tubes, it specifies their use in pipeline systems for fluid transmission like oil, gas, water, and slurry. Notably, for pipes smaller than NPS 12 (DN 300), the actual diameter may differ from the nominal size due to variations in wall thickness and internal diameter. ASME B36.10 M accommodates this disparity by accepting both the old standard thickness and nominal size.

In ASME B36.10M, pipe schedule is identified as Standard (STD), Ex-Standard (XS), or Double Extra Strong (XSS), or by Schedule No. 5, 10, 20, 30, 40, 80, 120, 160.

ASTM B36.19M specifies stainless steel pipe dimensions, including seamless and welded types, similar to the previous standard. Notably, for NPS 14 to NPS 22 (DN 350-550), it introduces Schedule 10S; for NPS 12, Schedule 40S; and for NPS 10 and 12, Schedule 80S, with the suffix “S” indicating different thicknesses compared to B36.10M.

Steel pipe schedule, denoted by ASME B 36.10, serves as a crucial indicator in various standards, commonly marked with “Sch.” This abbreviation, standing for schedule, typically precedes a series number, such as Sch 80, where “80” corresponds to a pipe number specified in chart/table ASME B 36.10.

Given that steel pipes primarily transport fluids under pressure, their internal diameter, known as nominal bore (NB), holds paramount importance. The pipe’s strength and wall thickness become critical factors, especially when carrying pressurized fluids. Hence, wall thickness is delineated in schedules, abbreviated as SCH, according to ASME standards.

The pipe schedule formula is represented as:

Sch. = P / [σ]t × 1000

Where:

Understanding and applying this formula aids in determining the appropriate schedule for steel pipes, ensuring they possess sufficient strength and wall thickness to withstand the designated pressure and operational conditions.

When discussing steel pipe parameters, the term “SCH” refers to pipe schedule, a method used to represent pipe wall thickness with numbers. Pipe schedule is not an actual wall thickness but rather a series of wall thicknesses. Different pipe schedules indicate varying wall thicknesses for pipes of the same diameter. Common indications of schedule include SCH 5, 5S, 10, 10S, 20, 20S, 30, 40, 40S, 60, 80, 80S, 100, 120, 140, and 160. As the schedule number increases, the wall thickness of the pipe also increases, resulting in higher pressure resistance. Therefore, a larger schedule number implies a thicker pipe wall, capable of withstanding greater pressure.

Schedule 40 and 80 steel pipes are ubiquitous in various industries, and understanding their significance is crucial for newcomers to the pipe industry. These designations denote the thickness of the pipe walls, with Schedule 40 and 80 pipes capable of withstanding higher pressures compared to lower schedules. As a result, they are in high demand across industries requiring robust piping systems.

The material standards for pipes of such thicknesses are versatile, accommodating various industry requirements. Whether it’s Schedule 40 stainless steel pipes like ASTM A312 Grade 316L or Schedule 40 carbon steel pipes such as API 5L, ASTM A53, ASTM A106B, A 179, A252, or A333, the options are extensive, catering to diverse applications and operational conditions.

Nominal Pipe Size (NPS) constitutes a standardized set of sizes for pipes employed in various pressure and temperature conditions, primarily in North America. This sizing convention employs two non-dimensional numbers: a nominal pipe size (NPS) specified in inches and a schedule (Sched. or Sch.) indicating the pipe’s thickness.

Nominal Diameter (DN), also recognized as the outside diameter, serves to denote the general diameter of pipes and pipeline accessories. Given the thin wall of pipes, the outside and inside diameters are nearly identical. Consequently, the average value of both parameters is utilized as the nominal diameter of the pipe. DN ensures interoperability among pipes and fittings of the same nominal diameter, facilitating interchangeability. Although the nominal diameter closely aligns with the inside diameter of the pipe, it does not precisely reflect the pipe’s actual diameter. Denoted by a numerical symbol followed by the letter “DN,” the unit is expressed in millimeters after the symbol. For instance, DN50 signifies a pipe with a nominal diameter of 50 mm. Understanding these sizing standards is essential for selecting and deploying appropriate piping solutions across diverse applications.

Certainly! Here are the conversions for Nominal Diameter (DN) in millimeters to Nominal Pipe Size (NPS) in inches:

DN (mm) | NPS (inch) |

6 | 1/8 |

8 | 1/4 |

10 | 3/8 |

15 | 1/2 |

20 | 3/4 |

25 | 1 |

32 | 1 1/4 |

40 | 1 1/2 |

50 | 2 |

65 | 2 1/2 |

80 | 3 |

2. Conversion for diameters equal to or greater than DN100 and NPS:

DN = 25 * NPS

NPS = DN / 25

3. Exact conversion:

1 inch = 25.4 mm

These conversions facilitate the interchangeability between Nominal Diameter (DN) and Nominal Pipe Size (NPS) measurements commonly used in piping standards.

The WGT class (weight class) delineates pipe wall thickness, comprising three grades: STD (standard), XS (extra strong), and XXS (double extra strong). Initially, only STD specifications existed for each pipe size. However, the need for pipes capable of handling high-pressure fluids led to the introduction of thicker XS pipes. Subsequently, XXS pipes emerged to accommodate even higher pressure requirements. With advancements in materials processing technology, there arose a demand for more cost-effective, thin-walled pipes, giving rise to the aforementioned pipe grades. The relationship between pipe schedules and weight classes is specified in ASME B36.10 and ASME B36.19 standards.

Standard steel pipe sizes vary depending on the application and industry standards. Common diameters include 0.5 inches (15 mm), 0.75 inches (20 mm), 1 inch (25 mm), 1.5 inches (40 mm), 2 inches (50 mm), 3 inches (80 mm), 4 inches (100 mm), 6 inches (150 mm), 8 inches (200 mm), 10 inches (250 mm), 12 inches (300 mm), 14 inches (350 mm), 16 inches (400 mm), 18 inches (450 mm), and 20 inches (500 mm).

To calculate the size of a pipe, measure its circumference with a flexible tape. Then, divide the circumference by pi (approximately 3.14159) to find the outside diameter. For example, a circumference of 12.57 inches (319 mm) would correspond to an outside diameter of about 4 inches (100 mm).

Pipe fitting size refers to the nominal size of the fitting, which corresponds to the size of the pipe it fits onto. For example, a half-inch pipe fitting is designed to fit over a pipe with a nominal diameter of half an inch. However, it’s important to note that the actual dimensions of the fitting may differ slightly from the nominal size, so it’s essential to consider both nominal and actual sizes when selecting fittings for a piping system.

Sheet Metal Gauge Chart When working with sheet metal, you often hear the term “gauge.” For those not familiar with…

Weight Formula for Steel In the world of metals, getting the weight of steel right is like hitting the bullseye…

SPFH590 Chemical Composition SPFH590 steels, as defined by the JIS G 3131 standard, are hot-rolled steels widely used across various industries.…