The law of physics always allows the driving energy in a system to flow until equilibrium. Heat dissipates when there is a temperature difference.

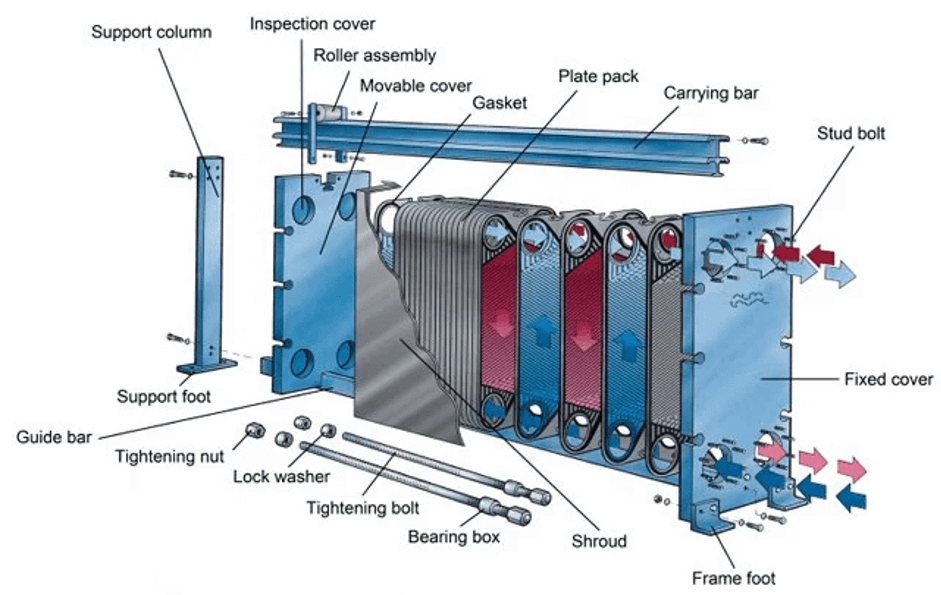

A heat exchanger follows the equalisation principle. With a plate heat exchanger, heat cuts through the surface and separates the hot medium from the cold. Thus, heating and cooling fluids and gases use minimal energy levels.

Speaking of Heat Exchangers, specialised boiler tubes are utilised in the proper functioning of such exchangers. SA179tube.com Is one leading Manufacturer, Supplier & Stockist Of Boiler Tubes A519 Mechanical Tubing.

The theory of heat transfer between mediums and fluids happens when:

- Heat is always transferred from a hot medium to a cold medium.

- There must always be a temperature difference between the mediums.

- The heat lost from the hot medium is equal to the amount of heat gained by the cold medium.

Generally, these plates are corrugated in order to increase the turbulence, the thermal exchange surface and to provide mechanical rigidity to the exchanger. Corrugation is achieved by cold forging of sheet metal with thicknesses of 0.3mm to 1 mm.

The most frequently used materials for the plates are stainless steel (AISI 304, 316), titanium and aluminium.The corrugation on the plates forces the fluid on a tortuous path, setting a space between two adjacent plates b, from 1 to 5 millimetres.

The fluids can cross the channels in series (a less common solution) or in parallel by making counter-current or current configurations.The serial configuration is used when there is a small flow rate for each fluid but high heat jump; the greatest problem is with a high pressure drop and an imperfect counter-current.

The parallel configuration with countercurrent channels is used for high flow rates with moderate temperature drops, and is the most widely used.When there is a great difference between the flow rates (or between the maximum permissible pressure drop) of the two fluids, the exchanger can run twice by the fluid with a lower flow (or higher losses) to balance the values of pressure drops or specific flow rates in the channels.

The working principle of a plate heat exchanger is determined by its construction, function, and application. A plate heat exchanger is a class of heat exchangers for transferring heat between two fluids using metal plates.

The plate heat exchanger has a notable advantage over conventional heat exchangers because the fluids are exposed to a much broader surface area as the fluids are spread over the plates. This facilitates heat transfer and considerably increases the rate of the temperature change.

Today, plate heat exchangers are common, and very tiny brazed ones are applied in the hot-water parts of millions of combination boilers. The high efficiency of such small dimensions leads to an increase in the Domestic Hot Water (DHW) flow rate of combination boilers. The small plate heat exchanger has a great influence on domestic heating and hot water supply. Larger commercial plate heat exchangers employ gaskets between the plates, while smaller ones can be brazed.

SA179tubes.com is a leading supplier, stockist, manufacturer & exporter of A519 Mechanical Tubing. Get in touch with us for the best rates & availability.