Heat Exchangers transfer or exchange heat between two fluids without mixing and come in various types depending on the design, application, required space, and fluid flows in the system. The heat exchangers have a barrier that separates the fluids and allows heat transfer simultaneously.

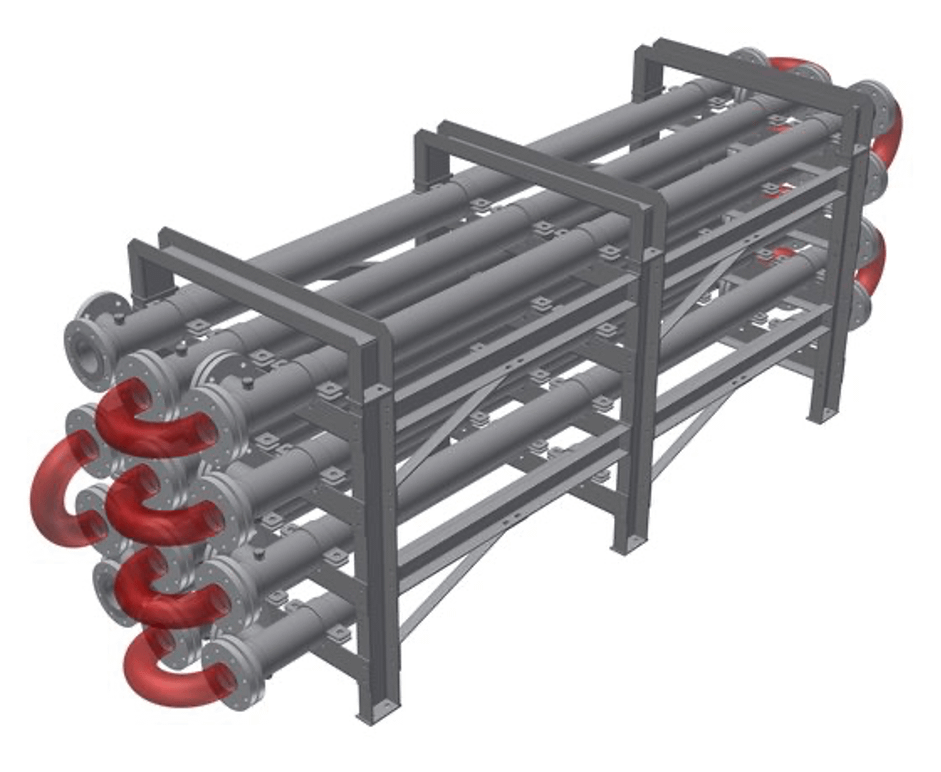

The double pipe heat exchanger is one of the most basic types of exchangers with a very flexible configuration. There are two types of counterflow or parallel flow for this type of pipe, which are the basis for determining pipe size, length, and the number of bends. In this article, we’ll explore different aspects of double pipe heat exchangers.

Speaking of Heat Exchangers, specialised boiler tubes are utilised in proper functioning of such exchangers. SA179tube.com Is one leading Manufacturer, Supplier & Stockist Of Boiler Tubes A210 Tubes And SA 210 Tubes.

Heat exchangers with double pipes

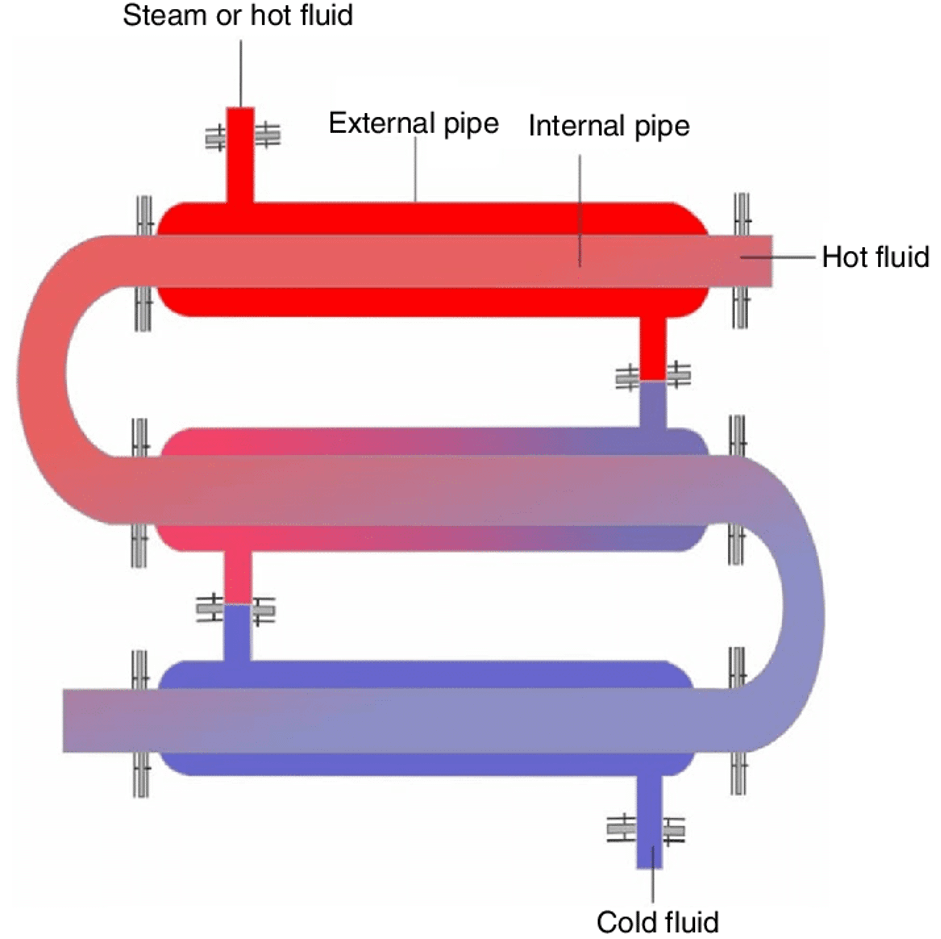

In a double pipe heat exchanger, we have a large pipe with a small pipe inside it concentrically, and all the heat transfer occurs in the larger pipe. As a conductive barrier, a small pipe flows one fluid through its interior and another fluid flows between the inner and outer pipes. Outside or shell side fluid flow includes inner side fluid flow.

This type of heat exchanger is also known as a hairpin, jacketed pipe, jacketed u-tube, and pipe in pipe exchanger. One pipe or pipe bundle can be contained (less than 30), and the outer pipe must have a diameter of less than 200mm. In some instances, longitudinal fins in the inner tube are used to increase heat transfer between working fluids.

Specification and Applications

A double pipe heat exchanger is one of the simplest heat exchangers. There are many options available to a customer because of the straightforward design. There are a wide variety of custom heat exchangers available in the market to satisfy industry and project needs. This type would be best suited for low capacity applications, where the heat transfer area is less than 45 square metres.

It is important to know what type of fluid you are using when using this exchanger. Viscous fluids should be used on the shell side due to the larger space available in the flow. Therefore, if you are using steam as a fluid in the exchanger, it would be better to use pipes.

A proper exchanger should be selected based on the project specifications. It should meet the required temperature and transfer requirements. When you provide these details, you make it easier for a supplier to introduce exchangers on the market or design the right pipe pairs for you. It was discussed before that the design of a double pipe heat exchanger is simple and modular, but if you increase the exchanger’s surface area, you’ll have to pay a lot more for it.

Because of their simple, elegant, and practical design, double pipe heat exchangers are suitable for a wide range of applications. Listed below are just a few:

- Boilers and compressors, as they operate at high temperatures and pressures

- Heating and cooling in process engineering

- Refining petroleum

- Treatment of sewage

Try double pipe heat exchangers for your project if space is an issue and you do not need a complex heat exchanger.

Different types of double pipe heat exchangers

The direction of flow can be used to categorise double pipe heat exchangers. Parallel and counter flows can be deployed in these exchanges, and it all depends on where the inlets and outlets are positioned. Parallel and counter flow affect the heat transfer and pressure drop in the system, and, by the way, in some applications, you should choose one over the other.

Double-pipe counter-flow heat exchangers

Counterflow is the best design for double pipe heat exchangers. Using this pattern, the heat exchanger has the best heat transfer coefficient and can either cool or heat the outlets as needed.

The flows flow in the opposite direction of each other, and at the end in both heads, we have the maximum temperature difference between fluids. Examine the diagram for the counter flow and consider fluid 1is hot and fluid 2 is cold. Cold side temperature at the outlet (T2out) can obtain temperatures close to the T1in, and as we know, this temperature is greater than T1out. In this type, the cold fluid temperature can reach more than the hot side outlet, while in the parallel one, it is impossible.

The advantages of double pipe heat exchangers

Heat exchangers of this type have a few unique advantages over others. Here are a few of these advantages:

- Providing good efficiency at lower capital costs is possible.

- Compared to shell and tube, they are smaller and require less space for maintenance, while the heat transfer is acceptable.

- They are very popular, so all the parts have been standardized, which makes repair and maintenance easier.

- A flexible design allows them to be easily added to or removed.

- High pressures and temperatures can be handled by this type of exchanger.

- Unlike expansion joints, the design of the exchanger allows for more thermal expansion.

The disadvantages of double pipe heat exchangers

As a result, you should be aware of the following flaws:

- These are usually used in counterflow designs and cannot be used in some applications. This does not mean that they cannot be used in parallel flow designs.

- They are limited by heat transfer rather than complicated designs and should be used in low heat applications.

- Leaking occurs more often in this type (with more units).

SA179tubes.com is a leading supplier, stockist, manufacturer & exporter of A210 Tubes & SA 210 Tubes. Get in touch with us for the best rates & availability.