The main differences between the fire tube and the water tube boiler are that hot gases flow inside the tube and water surrounds them in the fire tube boiler, whereas in the water tube, hot gases surround water.

On board a ship, boilers are used to generate power, and they are one of the most important components.

Speaking of Boiler Tubes , specialised boiler tubes are utilised in the proper functioning of the Boiler Tube. SA179tube.com Is one leading Manufacturer, Supplier & Stockist Of Seamless SA213 T2 Tubes.

How A Water Tube Boiler Works

The water tubes in a water tube boiler are heated externally by fire. The tubes are connected to a steam drum and a mud drum, and steam is produced in the upper drum. Instead of tubes heating water as in a fire tube boiler, water in the tubes directly generates steam. Water tube boilers are used more for industrial applications and less for heating purposes.

Larger facilities, such as hospitals and universities, commonly use these types of commercial boilers. Due to the smaller amount of water in the boiler, they pose a lower risk of catastrophic failure.

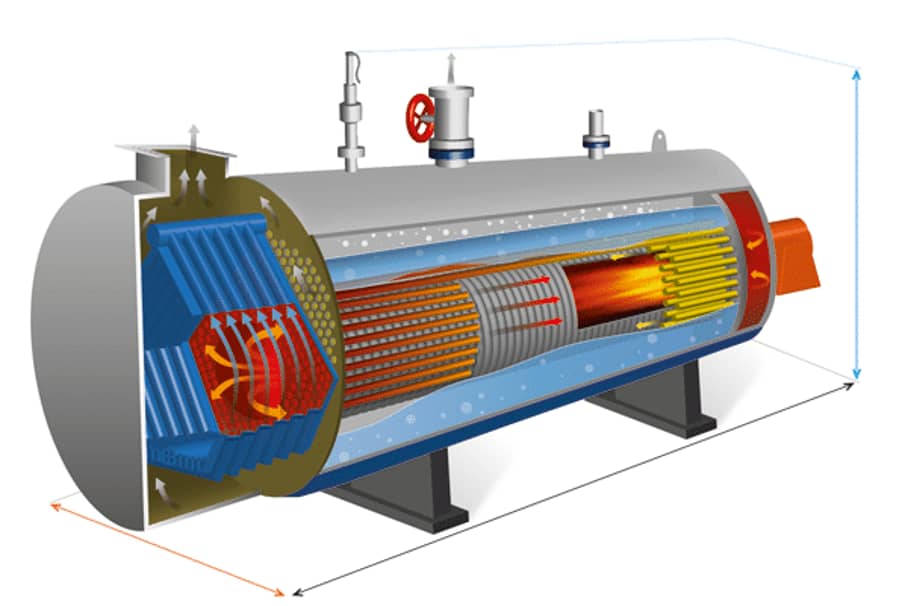

How A Fire Tube Boiler Works

Thermal conduction transfers heat through tubes in a fire tube boiler, which then heats the water in the container and produces steam. Essentially, the boiler is the pressure vessel that contains the water. A fire tube boiler is used in steam or hot water applications when it meets the guidelines in ASME Sections I and IV. It can also be used to evaporate liquids other than water.

For both low and high-pressure steam, as well as hot water, fire tube boilers are ideal. Commonly, they are used for applications that don’t exceed 350 psi. Typically, they have a capacity of 600,000 btu/hr to 50,000,000 btu/hr, but they can also have a capacity of 500,000 btu/hr to 75,000,000 btu/hr. This commercial boiler features easy-to-replace fire tubes, making maintenance simple.

S.no | Fire tube boiler | Water tube boiler |

1. | Flue gases are present inside the tubes of this boiler and water surrounds them | There is water inside the tubes and hot flue gases surround them |

2. | Low-pressure boilers. Their operating pressure is about 25 bar. | 165 bar is the operating pressure of these high pressure boilers. |

3. | The steam generation rate of a fire tube boiler is low, i.e. 9 tonnes per hour. | In water tube boilers, steam is generated at 450 tonnes per hour. |

4. | Steam generation requires more floor space for a given power source, i.e. 8 m2 per tonne per hour. | Steam generation requires a smaller floor space, i.e. 5 m2 per ton per hour. |

5. | This type of boiler is difficult to transport and erect. | The parts of the structure can be separated for easy transportation and erection. |

6. | This boiler has an overall efficiency of up to 75%. | With the economizer, the overall efficiency is up to 90%. |

7. | It can handle fluctuating loads for a shorter period of time. | All the time, it works with fluctuating loads. |

8. | The direction of water circulation in a fire tube boiler is not well defined. | The direction of water circulation in a water tube boiler is well defined i.e. a definite path is provided for the circulation of water. |

9. | Operating cost is low. | Operating cost is high. |

10. | Bursting chances are less in a fire tube boiler. | Bursting chances in a water tube boiler are more. |

11. | Due to bursting, there is a greater risk of damage to the boiler. | The bursting in this boiler does not produce any major destruction to the whole boiler. |

12. | It can be operated with less skilled people. | A skilled person is required to operate this boiler. |

13. | Low maintenance cost. | High maintenance cost. |

14. | They are light in weight. | They are heavy in weight. |

15. | It is suitable for small power plants. | It is suitable for large power plants. |

The most common types of these units are used for forced air heating and cooling systems, such as wood furnaces, boilers, stoves, and many others. ALFA water-to-air heat exchangers are also suitable for liquid cooling, as well as for a variety of liquid-to-air and liquid-to-liquid heat transfer applications.

Aluminium is used as the fin material because of its high heat conductivity. The fin density is an impressive 12 fins per inch. It has a unique design that allows for heating loads of 50,000 to 60,000 Btu per square foot. Despite the high fin density, the flow resistance through the coils is surprisingly low.

On the heat exchanger, there are two copper manifolds with smaller diameter copper tube coils running from side to side. Tube coils are accompanied by aluminium fins, which maximise heat transfer between water and air. A metal frame is used to reinforce the construction of the air to water heat exchanger.

When hot water or another suitable solution is introduced into the supply manifold of the water to air heat exchanger, it is separated into tube coils, which carry it throughout the heat exchanger to the return heat exchanger. Using a heat exchanger for cooling applications is similar to using cold water or other cooling liquid.

SA179tubes.com is a leading supplier, stockist, manufacturer & exporter of Seamless SA213 T2 Tubes . Get in touch with us for the best rates & availability.