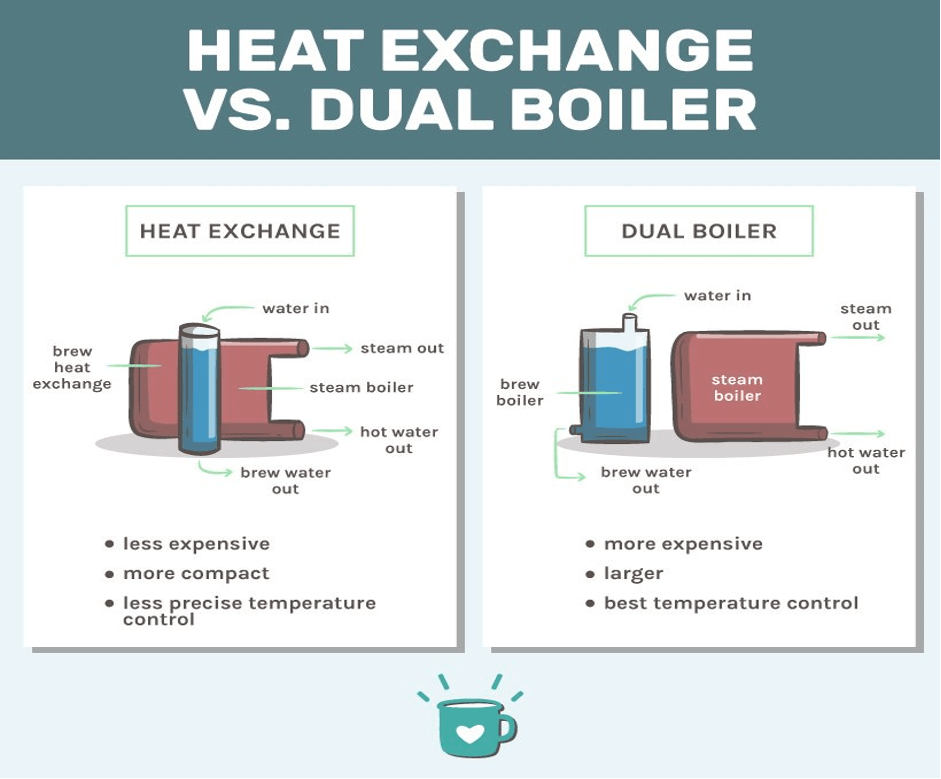

A Dual boiler espresso machine has two boilers, whereas a heat exchanger machine only has one. Although this is the most obvious difference between the two types of machines, both can produce extremely high steam temperatures and temperature below boiling for quality espresso. SA179tubes.com Is The Leading Manufacturer Of A192 tube & SA 192 tubes.

Speaking of Heat Exchangers, specialised boiler tubes are utilised in proper functioning of such exchangers. SA179tube.com Is one leading Manufacturer, Supplier & Stockist Of A192 Tube & SA192 Tubes.

Heat Exchanger

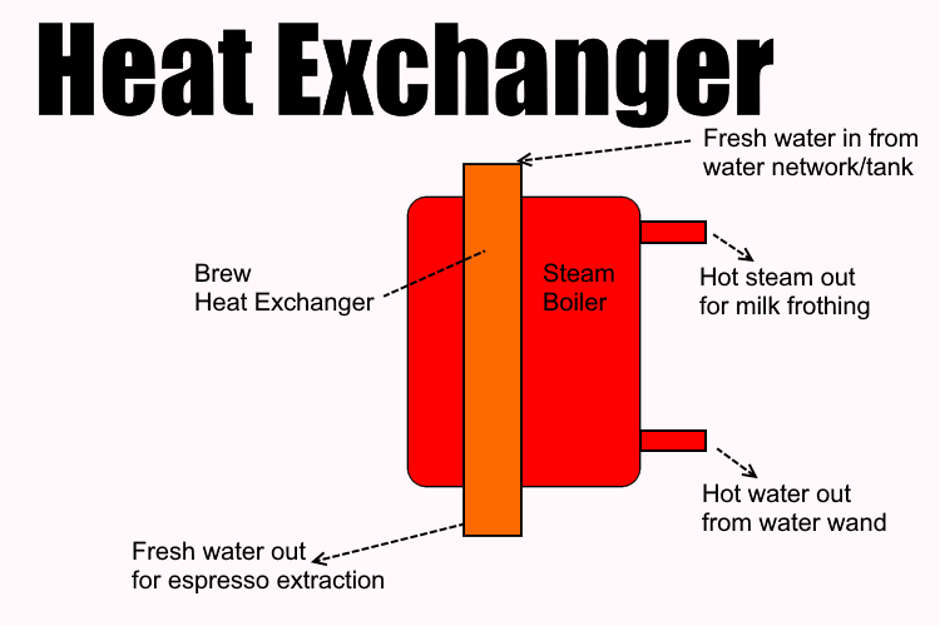

In a heat exchanger espresso machine like the Rocket Appartamento, water is kept at a temperature high enough to produce steam, approximately 255 – 265 degrees Fahrenheit. Water from the reservoir is fed into the steam boiler where it is flash heated before being channelled into the group to make the coffee. The steam boiler is half filled with water and has a heat exchange tube inside.

The steam valve above the water and heat exchanger tube is where steam is drawn from to create steam and make your milk-based drinks. Dual boiler machines do not require cooling flushes when the machine sits idle for a period of time, as is the case with heat exchangers.

But how does this principle apply to an espresso machine, and what does it mean for its performance?

Heat exchanger boilers in espresso machines differ from standard boilers in how they heat and control the water. Standard boilers pull water directly from the boiler for both steam and brew, but heat exchangers separate this process. The water temperature difference between steaming and brewing is over 40 degrees Fahrenheit. You’ll have to wait for temperature changes between brewing and steaming. The vast majority of commercial machines use heat exchangers or dual boilers to steam. This is why the vast majority of commercial machines have a heat exchanger or dual boiler. A912 Tube & SA 192 Tubes Are Used In Both Heat Exchanger & Dual Boiler.

The first thing we need to understand is what a heat exchanger actually is. Simply put, this is a boiler that transfers heat from one fluid to another without contacting the fluids. Imagine a pool of water with a tube running through it.

Water in the pool will affect the temperature of the water in the tube, and vice versa, despite the tube’s material separating them. Thousands of homes, businesses, and industries use these types of boilers. It’s likely you have at least one heat exchanger in your home, whether it’s your water heater, coffee machine, or some other appliance!

Dual Boilers

Dual boiler machines are just what they sound like: they have multiple boilers. Instead of a single boiler with multiple water paths, dual boilers have separate brew and steam boilers. The boiler can be ready at all times for either task.

The end result is that temperature is no longer a factor in shot inconsistency. In a machine like this, it’s nearly impossible for a barista’s shot preparation to outrun brew boiler recovery. As with a heat exchanger, a dual boiler allows you to steam and brew at the same time. Both boilers are temperature stable within the required ranges for both brewing and steaming, providing excellent consistency in both processes.

In high steam volume situations, such as steaming 10-20 oz. of milk, this can only change. Several lattes at once. With a Dual boiler, however, brew temperatures will not fluctuate and will result in consistent espresso.

What’s the problem? Cost, as you might have guessed. Dual boiler machines tend to be more expensive than heat exchangers because they pack in more material. Heat exchangers take up the same amount of space as a single boiler, functionally. Dual boiler machines, however, require double the materials. Over time, this means double the components that could fail. This also means double the space needed. This is another problem with dual boiler machines, as they tend to run larger.

Taking these caveats into consideration, dual boilers are powerful solutions for high volume cafés, especially when you actually have multiple baristas using the same espresso machine.

SA179tubes.com is a leading supplier, stockist, manufacturer & exporter of A192 Tube & SA192 Tubes. Get in touch with us for the best rates & availability.

A dual boiler espresso machine has two boilers, while a heat exchanger espresso machine only has one.

The steam boiler is half filled with water and has a heat exchange tube inside.

Dual boiler machines do not require cooling flushes when the machine sits idle for a period of time, as is the case with heat exchangers.

Dual boiler espresso machines have two boilers, while heat exchanger espresso machines have only one.

Rocket Appartamento’s heat exchanger espresso machine produces steam at 255 – 265 degrees Fahrenheit, a temperature high enough to produce steam.

Steam is drawn from the steam valve above the water and heat exchanger tube to make your milk-based drinks.