Welcome to SA179 Tubes, your premier supplier of high-quality Finned Tube Heat Exchangers.We pride ourselves on delivering cutting-edge solutions that meet and exceed your heat exchange requirements.

At SA179 Tubes, we understand the critical role that heat exchangers play in various industries. That’s why we are dedicated to providing you with products of unparalleled quality and performance. Our Finned Tube Heat Exchangers, featuring SA179 Tubes, stand as a testament to our commitment to excellence.

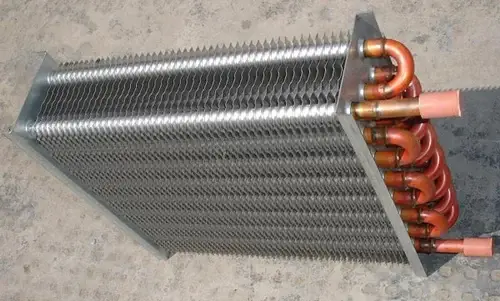

Key Features of Our Finned Tube Heat Exchangers

- Premium Materials: We exclusively utilize SA179 Tubes in the construction of our heat exchangers. Renowned for their exceptional thermal conductivity and durability, SA179 Tubes ensure optimal heat transfer efficiency and longevity.

- Innovative Fin Designs: Our heat exchangers boast state-of-the-art fin designs, optimizing surface area for enhanced heat dissipation. This innovation translates to improved overall performance, making our products ideal for a wide range of applications.

- Custom Solutions: Recognizing that each project is unique, we offer customizable FINNED TUBE HEAT EXCHANGER solutions tailored to your specific requirements. Our engineering team works closely with you to design a product that seamlessly integrates into your system.

- Reliability and Durability: SA179 Tubes, combined with our rigorous quality control processes, ensure the reliability and durability of our heat exchangers. You can trust our products to withstand the most demanding operational conditions, providing consistent performance over the long term.

The Advantages of Aluminum in Finned Tube Heat Exchangers

- Lightweight Design: Aluminum’s lightweight nature stands out as a key advantage in the construction of Finned Tube Heat Exchangers. Compared to heavier metals such as stainless steel or copper, aluminum allows for the creation of heat exchangers that are more manageable and easy to install. This quality is particularly beneficial in applications where weight is a critical factor.

- Enhanced Radiator Performance: In the realm of radiators, the use of lightweight aluminum significantly improves equipment performance. The reduced weight contributes to more efficient heat transfer, enabling the radiator to operate optimally without placing undue stress on the supporting structure. This characteristic makes aluminum an ideal choice for industries where equipment efficiency is paramount.

- Superior Heat Conductivity: One of the standout features of aluminum is its exceptional heat conductivity. When it comes to radiators, this property translates to rapid and efficient heat dissipation. Aluminum radiators can quickly reach the desired operating temperature, ensuring a prompt response to heating requirements. This makes them a preferred choice for applications where fast and effective heat exchange is crucial.

- Eco-Friendly Solution: Opting for aluminum radiators or fin tubes aligns with environmental consciousness. Aluminum is a highly recyclable metal, making it a sustainable choice for heat exchanger components. By choosing aluminum, you not only benefit from its performance advantages but also contribute to a greener and more eco-friendly approach to manufacturing and consumption.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that makes it resistant to corrosion. This property enhances the longevity of Finned Tube Heat Exchangers, ensuring a durable and reliable solution for various applications. The corrosion resistance of aluminum contributes to lower maintenance requirements and longer service life.

- Cost-Effective Solution: Aluminum’s availability and manufacturing efficiency contribute to its cost-effectiveness. Choosing aluminum for Finned Tube Heat Exchangers allows for the creation of high-performance systems without the added expense associated with some other materials. This affordability makes aluminum an attractive option for industries looking to balance performance and budget considerations.

Types of Finned Tube Heat Exchangers

Applications of Finned Tube Heat Exchangers

- Optimizing Heat Transfer in Varied Industries: Finned Tube Heat Exchangers play a crucial role in scenarios where the heat transfer coefficient within the fluid is higher than the fluid outside the tube. This unique characteristic makes them indispensable in industries where efficient heat exchange is paramount.

- Automobile Radiators: Among the notable applications of finned tube air heat exchangers are automobile radiators. In heavy trucks, the radiator’s primary function is to cool hot water circulating through the tubes. This cooling is achieved by circulating air through the fins in a crossflow pattern. Similarly, car radiators employ finned tube heat exchangers to regulate engine temperature and ensure optimal performance.

- Air Conditioner Evaporator Coils: Finned tube heat exchangers also find application in air conditioner evaporator coils. Here, the objective is to condense the air as it travels through the coils, contributing to the overall cooling process in air conditioning systems. The efficiency of these coils is crucial for maintaining comfortable indoor environments.

- Chemical and Petrochemical Industries: The chemical and petrochemical industries benefit significantly from the versatility of finned tube heat exchangers. These systems play a vital role in processes that require precise temperature control and efficient heat transfer, contributing to the overall productivity and reliability of operations.

- Dry Cooling for Steam Power Plants: Recent advancements in technology have led to the rapid growth of dry cooling systems for steam power plants. In this method, air-cooled condensers, often featuring finned tube heat exchangers, replace traditional water-cooled condensers. This transition minimizes water usage and provides a more sustainable solution for power generation.

- Customized Fins for Specific Purposes: Fins in finned tube heat exchangers are designed in unique shapes and sizes to serve specific purposes. For instance, S-shaped fins are employed in heavy truck radiators to increase the surface area for heat exchange, thereby enhancing the heat transfer rate. These innovations make modern truck radiators more efficient and reliable.

Supply and Exporter of Finned Tube Heat Exchangers in Cities like

Pimpri-Chinchwad, Chandigarh, Kuwait City, Ulsan, Ankara, Geoje-si, Hanoi, Noida, Secunderabad, Sharjah, Los Angeles, Ahmedabad, Caracas, Al Khobar, Mexico City, Jaipur, New York, Tehran, Gimhae-si, Muscat, Jakarta, Montreal, Perth, Chiyoda, Madrid, Pune, Baroda, Nagpur, Ludhiana, Surat, Melbourne, Lagos, Bengaluru, Kuala Lumpur, Algiers, Ernakulam, Haryana, Courbevoie, London, Dammam, Brisbane, Thane, Aberdeen, Hong Kong, Doha, Houston, Ahvaz, Bogota, Bangalore, Cochin, Anand, Nadiad, ankleshwar, Bharuch, vapi, Valsad, Medak, Godavari, Mumbai, Dallas, Santiago, Bangkok, New Delhi, Ranchi, Hyderabad, Lahore, Indore, Jeddah, Singapore, Kanpur, Moscow, Coimbatore, Seoul, Navi Mumbai, Granada, Chennai, Sydney, Istanbul, Colombo, Faridabad, Dubai, Howrah, Toronto, Rajkot, Karachi, Milan, Bhopal, Nashik, Cairo, Riyadh, Edmonton, Rio de Janeiro, Kolkata, La Victoria, Vung Tau, Gurgaon, Ho Chi Minh City, Thiruvananthapuram, Visakhapatnam, Petaling Jaya, Atyrau, Vadodara, Jamshedpur, Abu Dhabi, Al Jubail, Manama, Busan, Calgary, Port-of-Spain.

Supply and Exporter of Finned Tube Heat Exchangers in Countries like

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland.