When it comes to heat management systems, the design variances between heat exchangers and interchangers are crucial to comprehend. In chiller systems, cooling is facilitated by refrigeration units, whereas heat exchangers achieve temperature regulation through direct fluid heat transfer.

Lets explore the difference between heat exchangers and heat interchangers in this blog.

Speaking of Heat Exchangers, specialised boiler tubes are utilised in proper functioning of such exchangers. SA179tube.com Is one leading Manufacturer, Supplier & Stockist Of ASTM A106 pipe.

Exchanger Heat

A It is an apparatus used for heat recovery, which means it is used to transfer heat from two fluids. A heat exchanger and a condenser differ by the purpose of the state change of the substance (liquid or vapour).

Heat Interchanger

The utilization of heat interchangers has been a longstanding practice in the commercial refrigeration industry, often implemented without thorough consideration of theoretical or practical concepts. In this context, ASTM A106 Pipe and ASME SA106 Pipe play pivotal roles. They constitute essential elements of heat interchangers, integral to their proper functioning in refrigerant systems.

These pipes are employed in various ways and for diverse reasons within refrigerant heat exchangers. The incorporation of ASTM A106 Pipe and ASME SA106 Pipe ensures the efficiency and effectiveness of the heat exchange process in these systems.

By understanding the distinctions and applications of heat exchangers and interchangers, one can make informed decisions regarding their utilization in specific contexts.

Key Characteristics of Heat Exchangers:

1. Fluid Isolation: Heat exchangers maintain a physical separation between the fluids involved, ensuring they do not mix during the heat transfer process. This is crucial in applications where contamination or chemical reactions must be avoided.

2. Efficiency: Heat exchangers are engineered for efficiency, maximizing the transfer of thermal energy between the fluids while minimizing energy losses. This makes them essential in various industries, including HVAC systems, refrigeration, and power generation.

Key Characteristics of Heat Interchangers:

1. Same Fluid Streams: Heat interchangers operate by exchanging heat between streams of the same fluid, typically at different temperatures. This makes them suitable for applications where temperature equalization or balancing is required.

2. Temperature Adjustment: The primary purpose of a heat interchanger is to adjust the temperature of the fluid streams involved. This can be crucial in processes where precise temperature control is essential for optimal performance.

Practical Applications: Where Heat Exchangers and Heat Interchangers Shine

Heat exchangers and heat interchangers find their niche in a diverse array of applications:

Power Generation: Heat exchangers transfer heat from boilers to turbines, generating the steam that powers turbines.

Refrigeration and Air Conditioning: Heat exchangers remove heat from refrigerant, enabling cooling and air conditioning systems to function.

Industrial Processes: Heat exchangers are employed in chemical processing, petroleum refining, and various manufacturing applications.

Automotive Engineering: Heat interchangers enhance engine performance and fuel efficiency by cooling compressed air.

Increasing Suction Gas Temperature:

Refrigeration compressors are typically rated at suction gas temperatures significantly above freezing point. This heat is drawn from the evaporator to achieve the desired rating. In low-temperature applications, the evaporator may struggle to meet this requirement, resulting in a potential 5% shortfall in compressor rating and system capacity.

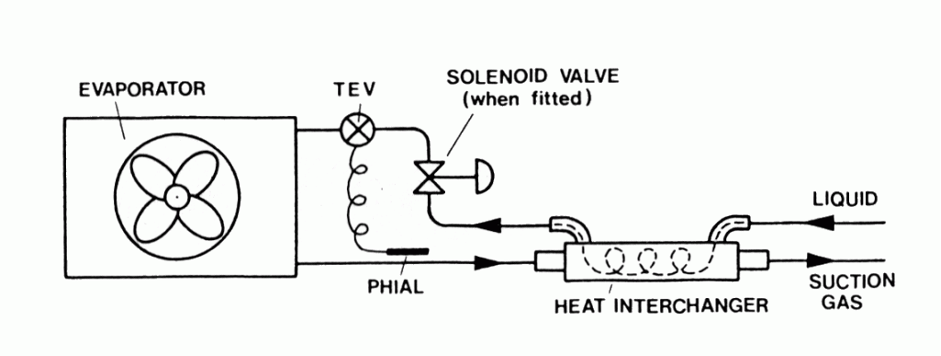

To indirectly achieve the necessary superheat, a properly-sized heat interchanger comes into play. This device can restore and sometimes slightly increase the system’s evaporator capacity by superheating the suction gas and subcooling the refrigerant liquid through an exchange of heat. The subheating obtained is then effectively utilized in the evaporator, addressing the requirements mentioned in the preceding paragraph.

Understanding and optimizing the role of heat exchangers, especially in low-temperature scenarios, is essential for maintaining compressor efficiency and overall system capacity.

The temperature interchange between the refrigerant vapor and the liquid is approximately equal too:

| Refrigerant type | Factor ‘C’ |

| R12 | 0.6 |

| R22 | 0.5 |

| R502 | 0.55 |

In refrigeration systems, the liquid refrigerant entering the compressor can pose a significant threat to mechanical components. However, a well-selected heat interchanger, designed for its standard duty, can effectively mitigate this risk. It achieves this by either boiling off or breaking up slugs of liquid refrigerant, particularly when such occurrences are intermittent.

This concern is particularly pronounced in applications with close approach conditions, such as low-temperature cold stores operating at low thermal expansion valve (TEV) superheats. These conditions increase the likelihood of instability, necessitating measures to protect the compressor.

Continuous influx of “wet” refrigerant vapor into the compressor can have detrimental effects on the lubricating system. The presence of liquid refrigerant can dilute the oil and induce foaming, leading to excessive wear and, in severe cases, the seizure of moving parts.

Moreover, this condition has a de-rating effect on the compressor’s pumping rate, affecting the system’s evaporator capacity. Simultaneously, the continual washing of oil off the cylinder walls contributes to an increased wear rate.

Understanding and addressing these challenges through the strategic use of heat interchangers is crucial for maintaining the efficiency and longevity of refrigeration systems, especially in applications with demanding operational conditions.

Increasing the degree of liquid subcooling as it enters the expansion valve:

Achieving optimal performance in a thermal expansion valve (TEV) and the entire refrigeration system hinges on ensuring a vapour-free liquid refrigerant at the TEV inlet. This is particularly crucial for the effective operation of the TEV.

One common challenge to this ideal condition is the presence of flash gas in the liquid line. This can occur due to factors such as the evaporator being positioned above the condenser or experiencing pressure losses in the pipelines. The existence of flash gas can compromise system efficiency and the precise functioning of the TEV.

To address this issue, the strategic implementation of a heat interchanger becomes essential. A heat interchanger effectively eliminates flash gas in the liquid line. By doing so, it ensures that the refrigerant reaching the TEV is in a vapor-free liquid state, optimizing the TEV’s performance and contributing to the overall efficiency of the refrigeration system.

Understanding and managing the degree of liquid subcooling, especially through the use of heat interchangers, is a key aspect of maintaining reliable and efficient refrigeration processes.

Based on refrigeration liquid at 32 ºC (90 ºF) the amount of subcooling required to compensate for these losses is:

| SI & METRIC UNITS | R12 | R22 | R502 |

| 1 bar pressure drop | 4.9ºK | 3.1ºK | 2.9ºK |

| 10m elevation difference* | 6.2ºK | 3.5ºK | 3.4ºK |

| IMPERIAL UNITS | R12 | R22 | R502 |

| 10 psi pressure drop | 6.1 ºF | 3.8 ºF | 3.6 ºF |

| 10ft elevation difference* | 3.4 ºF | 1.9 ºF | 1.8 ºF |

Minimum heat interchanger superheats and the approximate related subcooling for nominal selection are: –

| APPLICATION | SUPERHEAT | SUBCOOLING |

| High temperature, room above O ºC (32 ºF) | 10 ºK (18 ºF) | 5.5 ºK (10 ºF) |

| Commercial temperature, room below O ºC (32 ºF) | 15 ºK (27 ºF) | 8 ºK (14 ºF) |

| Low temperature, room below 20 ºC (-5 ºF) | 20ºK (36ºF) | 11 ºK (20 ºF) |

A realistic appraisal of heat interchanger usage would be:

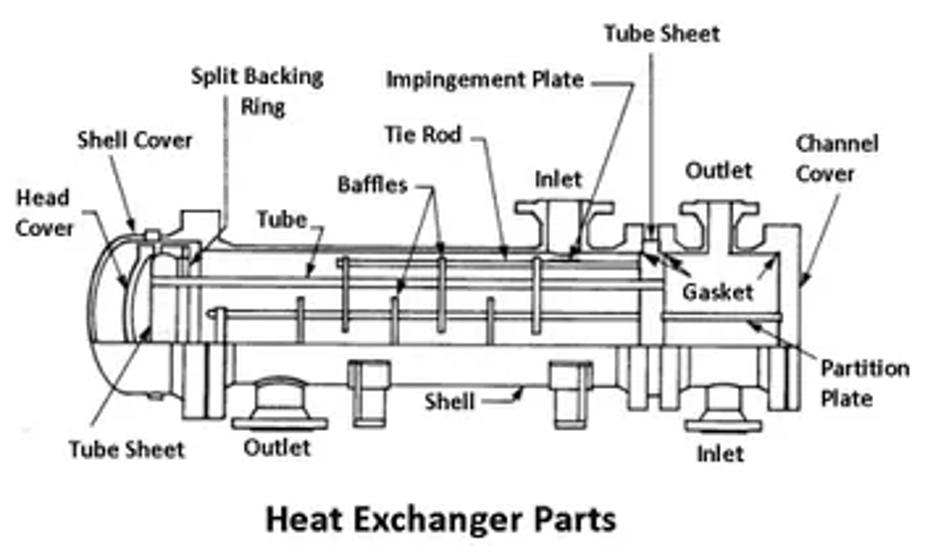

Classification of Heat Exchangers

Heat exchangers play a crucial role in various industries by facilitating the efficient transfer of thermal energy between fluids. They are categorized based on different principles and configurations. Here are three main classifications:

Direct Transfer Type:

In this category, hot and cold fluids are physically separated by a metal wall, through which heat is transferred from the hot fluid to the cold fluid.

An example of this type is a shell and tube heat exchanger, where one fluid flows through tubes while the other surrounds the tubes in a shell.

Storage Type:

In storage-type heat exchangers, a hot fluid passes through a porous solid to heat it. Subsequently, a cold fluid is circulated through the now-hot solid to extract heat.

Notably, this type of heat exchanger is not commonly employed in the pharmaceutical industry.

Direct Contact:

In direct contact heat exchangers, hot and cold fluids come into direct physical contact without a barrier. The hot fluid usually passes through or mixes with the cold fluid.

An illustrative example is the bubbling of steam through a cold liquid, demonstrating the direct interaction of the two fluids.

Understanding these classifications is fundamental to selecting the most suitable heat exchanger for specific industrial applications. Each type has its advantages and limitations, and the choice depends on factors such as efficiency, cost-effectiveness, and the nature of the fluids involved.

Conclusion:

In the grand narrative of thermal dynamics, let’s not forget the human touch within the dance of heat. Heat exchangers and heat interchangers, with their silent conversations and orchestrated symphonies, play vital roles in our daily lives and industrial landscapes. As we embrace the fluidity of their stories, we come to appreciate the warmth they bring to our world – a warmth not just in temperature but in the human touch of efficiency, comfort, and precision.

SA179tubes.com is a leading supplier, stockist, manufacturer & exporter of ASTM A106 pipe. Get in touch with us for the best rates & availability.

This heat is extracted from the evaporator to reach this rating.

The heat exchanger in this application has two effects

The hot and cold fluids are separated by a metal wall through which heat is transferred from the hot to the cold fluid.

An exchanger is a device for transferring heat from one fluid (hot gas or steam) to another fluid. A heat interchanger transfers heat between liquids or gases through a metal wall.

Heat exchangers and interchargers have very different designs

Chiller systems use refrigeration units for cooling, while heat exchangers use direct fluid heat transfer to regulate temperature.