Shell and tube heat exchangers are popular due to the flexibility the designer has to allow for a wide range of pressures and temperatures. Basically, there are two main types of shell and tube heat exchangers:

- Standards from TEMA, the Tubular Exchanger Manufacturers Association, tend to cover those used in the petrochemical industry.

- Those used in the power industry, such as feedwater heaters and power plant condensers.

Speaking of Heat Exchangers, specialised boiler tubes are utilised in the proper functioning of such exchangers. SA179tube.com Is one leading Manufacturer, Supplier & Stockist Of SA213 T2 Tubes.

There are a number of features that are common regardless of the industry in which the exchanger will be used

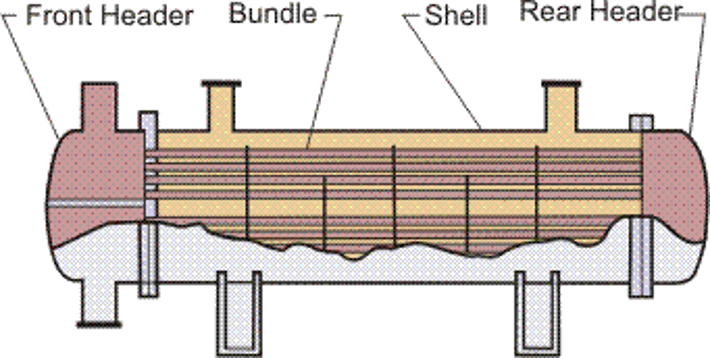

An exchanger consisting of tubes mounted inside a cylindrical shell is referred to as a shell and tube exchanger. In the figure, an example of a typical unit that can be found in a petrochemical plant is shown. Two fluids can exchange heat, one fluid flows over the outside of the tubes while the second fluid flows through the tubes. Fluids can be single or two phase, and can flow in parallel or cross-counter-flow.

Shell and tube exchangers have four major components

- The fluid enters the tube side of the exchanger through the front header. The stationary header is sometimes called this.

- In exchangers with multiple tubeside passes, this is where the tube side fluid leaves the exchanger or returns to it at the rear header.

- Tube bundle includes tubes, tube sheets, baffles, tie rods, etc. to hold the bundle together.

- Shell – contains the tube bundle.

The remainder of this section discusses exchangers that are covered by the TEMA standard.There are basically three types of combinations

- Tubesheet exchangers with fixed tubesheets

- Exchangers for U-tubes

- Exchangers for floating headers

Tubesheet Exchanger (for L, M, and N Type Rear Headers)

The tubesheet exchanger has the tubesheet welded to the shell. It results in a simple and economical construction, and tube bores can be cleaned mechanically or chemically. Despite this, the outside surfaces of the tubes cannot be cleaned except by chemical means.

If there are large temperature differences between shell and tube materials, it may be necessary to incorporate an expansion bellow in the shell to eliminate excessive stresses. A bellows of this type is often weak and prone to failure. If the consequences of failure are particularly severe, U-tube or floating header units are normally used.

Generally speaking, removable bundles are the least expensive design, but they are slightly more expensive at low pressures than fixed tubesheets.

U-Tube Exchangers

With a U-Tube exchanger, any of the types of front header can be used, and the rear header is normally an M-Type. U-tubes permit unlimited thermal expansion, the tube bundle can be removed for cleaning, and small clearances can be achieved between the bundle and the shell. Since it is difficult to clean the tubes internally by mechanical means, it is normal only to use this type where the tube side fluids are clean.

Floating Head Exchanger (P, S, T and W Type Rear Headers)

As with other types of exchangers, the tubesheet at the Rear Header end is not welded to the shell, but is allowed to float. The tubesheet at the Front Header (tube side fluid inlet end) has a larger diameter than the Seal and is sealed in a similar manner to that used in the fixed tubesheet design. The tubesheet at the rear header end of the shell has a slightly smaller diameter than the shell itself, allowing the bundle to be pulled through the shell. With a floating head, thermal expansion can be accommodated and the tube bundle can be removed for cleaning. Many types of rear headers can be used, but the most commonly used is the S-Type Rear Head. The floating head exchanger is suitable for the rigorous duties associated with high temperatures and pressures, but is more expensive (typically by 25% for carbon steel construction) than the equivalent fixed tubesheet exchanger.

SA179tubes.com is a leading supplier, stockist, manufacturer & exporter of SA213 T2 Tubes. Get in touch with us for the best rates & availability.

Shell and tube heat exchangers are a type of heat exchanger that comes in a variety of designs.

Despite this, the outside surfaces of the tubes cannot be cleaned except by chemical means.

Two fluids can exchange heat, one fluid flows over the outside of the tubes while the second fluid flows through the tubes.

There is a wide range of pressures and temperatures that can be accommodated by shell and tube heat exchangers.